Photolithographic 3D-Printing

3D printing and additive manufacturing are the breaking technology in tissue engineering.

The ability to simulate in vitro the natural environment for a cell culture can lead to faster developing of drugs and drastically decrease its cost.

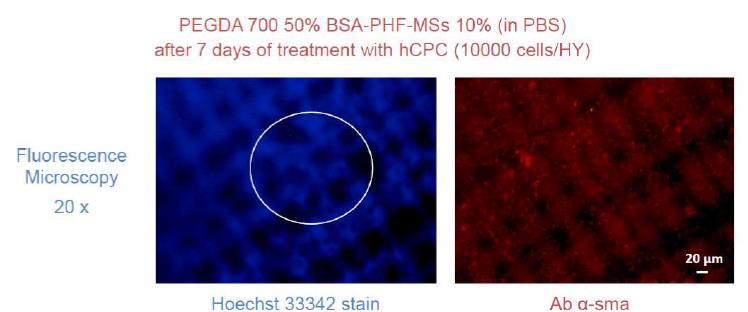

Another important aspect in this work is to provide a model to study how shape and mechanical properties of the scaffold influence the differentiation

of stem cells. The biocompatible material we are using in this project is the hydrogel, chosen for its ability to absorb large amount of water up to

1000 time its own mass.

3D printing and additive manufacturing are the breaking technology in tissue engineering.

The ability to simulate in vitro the natural environment for a cell culture can lead to faster developing of drugs and drastically decrease its cost.

Another important aspect in this work is to provide a model to study how shape and mechanical properties of the scaffold influence the differentiation

of stem cells. The biocompatible material we are using in this project is the hydrogel, chosen for its ability to absorb large amount of water up to

1000 time its own mass.

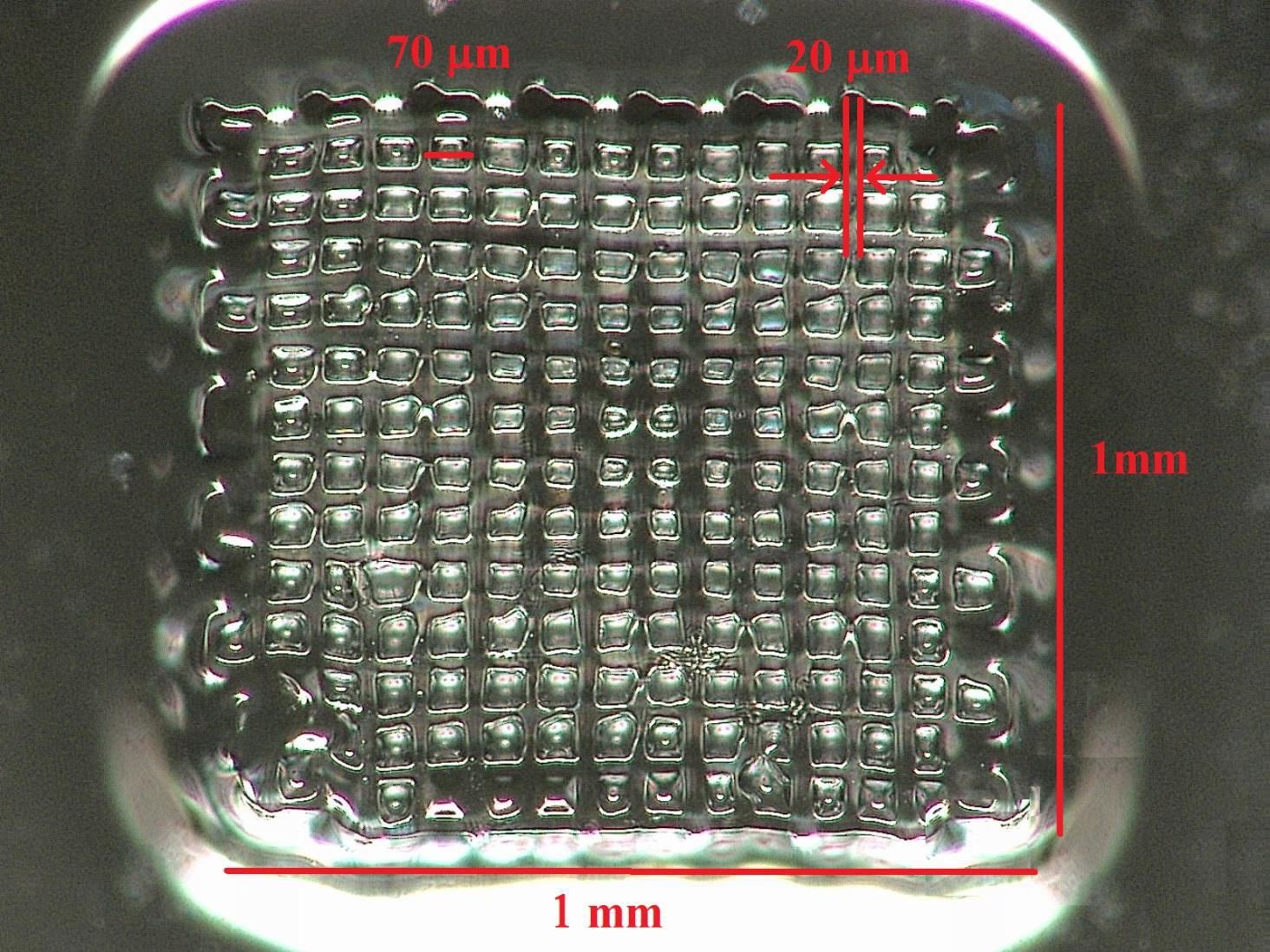

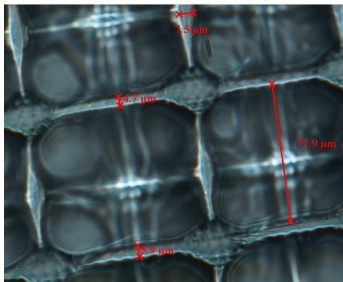

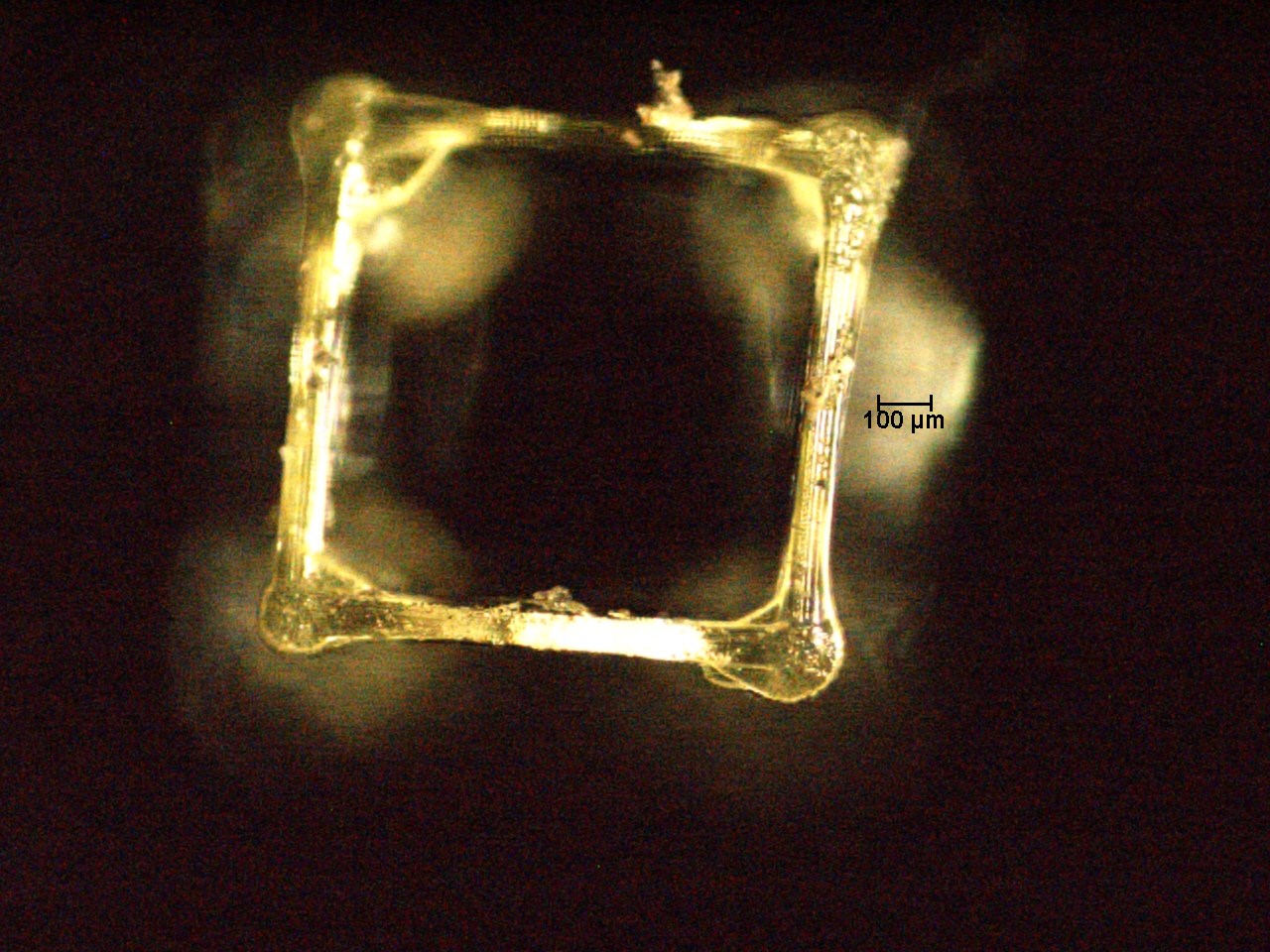

We realized scaffold based on high MW-PEGda (PoliEtilenGlicol diacrilate) via one- (2D) and two-photon polymerization using a femtosecond pulsed laser (3D).

Alternatively HDDA (1,6-Hexanediol-diacrylate) via a microstereolithographic approach using a liquid filter as a mean for depth control in the photopolymerization process.

Our goal is to study how the mechanical properties of the scaffold determinate the differentiation of stem cells.

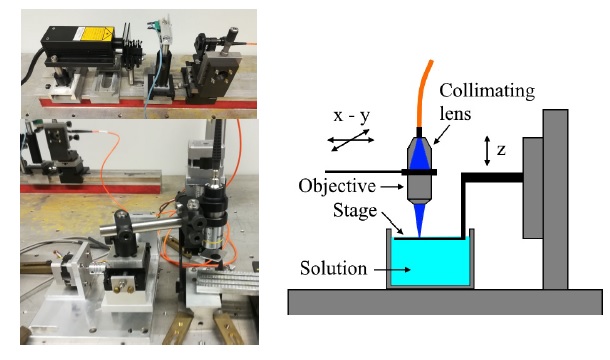

A simple direct laser writing method based on 1P microstereolithography exploiting the optical

characteristics of carefully selected photopolymerizable system (polymer, photoinitiator, optics) has

been implemented. Direct laser writing technique has been applied for micro-stereolithography in which we use as light source a low power blue

diode laser with a wavelength of 448nm.

Since the intensity of the light reduces by a factor 5 within a penetration depth, equal to the depth of focus of the optical

system, we achieve a fine control of the vertical and lateral photopolymerization of the solution. The threshold for effective

polymerization is not reached outside that region.

We collected the light at the exit of the fibre using a collimating lens (f=34.74mm, NA=0.26). A

microscope objective (10x NA=0.22) focused the beam on the polymer solution. The fibre exit and

the focusing optics were scanned by a micrometre x-y stage to realize a 2D pattern on the solution

surface layer.

A simple direct laser writing method based on 1P microstereolithography exploiting the optical

characteristics of carefully selected photopolymerizable system (polymer, photoinitiator, optics) has

been implemented. Direct laser writing technique has been applied for micro-stereolithography in which we use as light source a low power blue

diode laser with a wavelength of 448nm.

Since the intensity of the light reduces by a factor 5 within a penetration depth, equal to the depth of focus of the optical

system, we achieve a fine control of the vertical and lateral photopolymerization of the solution. The threshold for effective

polymerization is not reached outside that region.

We collected the light at the exit of the fibre using a collimating lens (f=34.74mm, NA=0.26). A

microscope objective (10x NA=0.22) focused the beam on the polymer solution. The fibre exit and

the focusing optics were scanned by a micrometre x-y stage to realize a 2D pattern on the solution

surface layer.

References

- F. Mochi, F. De Matteis, P. Prosposito, L. Burratti, R. Francini, M. Casalboni,

One Photon 3D Polymerization via Direct Laser Writing

Materials Science Forum, 941, 2142-2147 (2018)

- M. Ciocci, F. Mochi, F. Carotenuto, E. Di Giovanni, P. Prosposito, R. Francini, F. De Matteis, I. Reshetov, M. Casalboni, S. Melino, P. Di Nardo

Scaffold-in-Scaffold Potential to Induce Growth and Differentiation of Cardiac Progenitor Cells

Stem Cell Dev. 26(19) 1438-1447(2017)

- P. Prosposito, S. Melino, M. Ciocci, R. Francini, F. Mochi, F. De Matteis, P. Di Nardo,S. Ksenzov, S. Schrader, M. Casalboni,,

Photolithography of 3D scaffolds for Artificial Tissue

Materials Science Forum, 879, 1606-11 (2017)

- F. Mochi, P. Prosposito, R. Francini, F. De Matteis, S. Melino, M. Ciocci, P. Di Nardo, S. Ksenzov, S. Schrader, M. Casalboni,

Advanced biocompatible photolithographic scaffolds for tissue engineering

IET Conference Proceedings, p. 1-4 (2016)